Discover key benefits of the Home Energy Storage Solutions

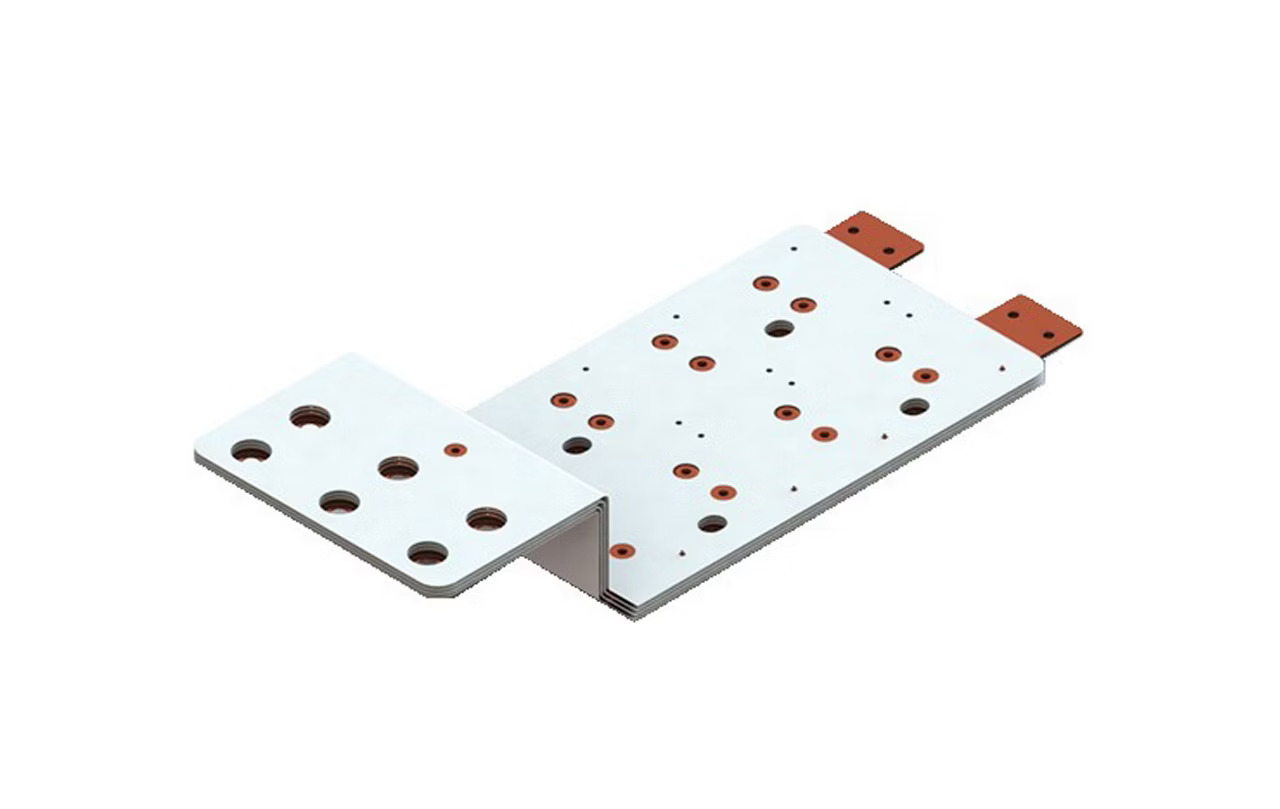

Busbars

- Swaging of rod Edge bend and complex forming

- Tin, Nickel,and Silver plating

- Powder coat insulation

- Brazing and welding

- Round and flat braid versions

- Insulated and uninsulated versions

- Stacked braid versions

- Flex/rigid combined solutions

- Improved heat dissipation

- Low characteristic impedance

- Powder coat solutions

- Tin, Nickel and Silver plating

- Automotive

- Industrial Automation

- Networking

- Telecommunications

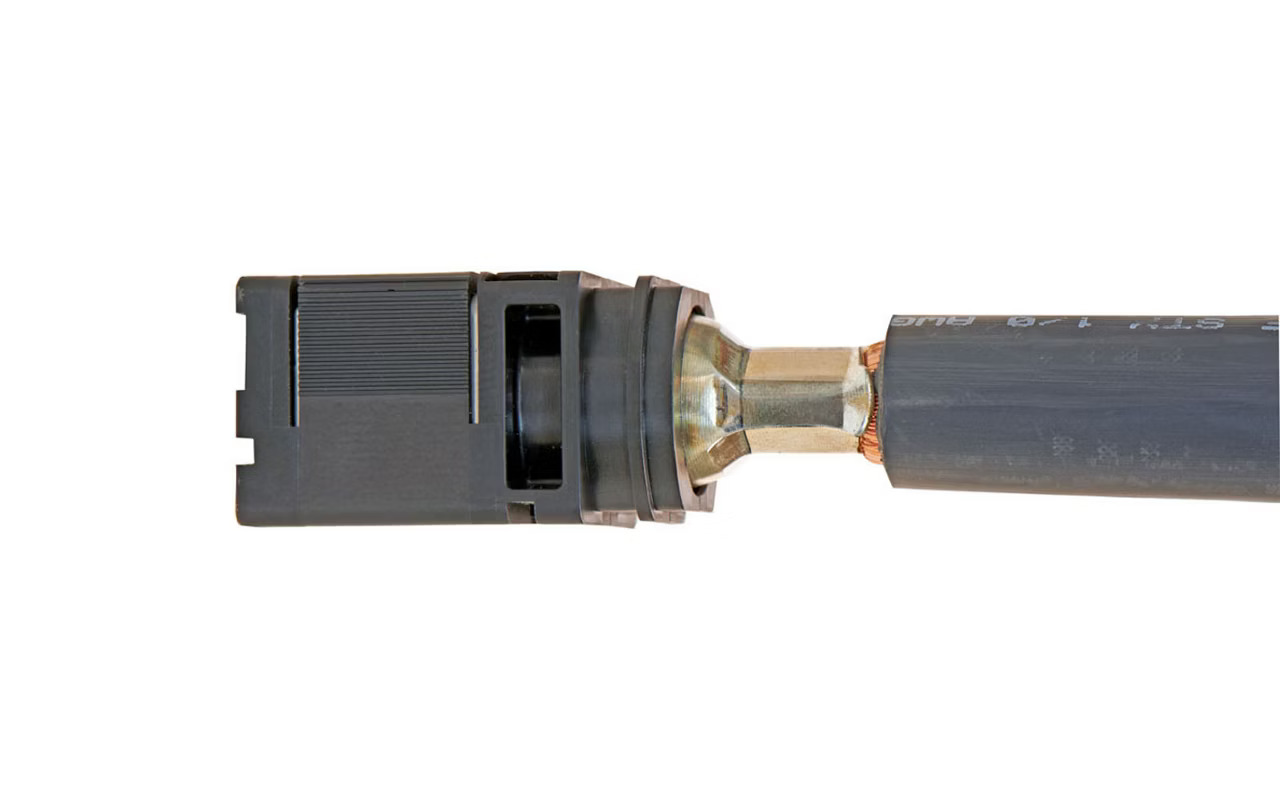

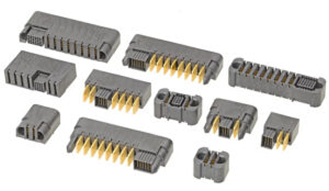

SW1 Connectors

Power efficiency is critical to cost and safety management in the power intensive applications within energy storage systems. SW1 receptacles incorporate Molex’s proven COEUR socket, which with its multiple contact beams creates a large contact surface at the mating interface, resulting in low contact resistance and voltage drop which leads to minimal heat generation.

Dense electronic packaging demands a low mated height between a cable assembly and its printed circuit board or busbar. SW1 receptacle assemblies are about 1/3rd lower in height and 1/3rd shorter in length than comparable solutions using hyperbolic sockets. The z-axis mating configuration is designed to eliminate cable bend radius complications, making it an ideal solution for applications where space is constrained.

Identifying high-current, high-voltage interconnect that can attach to either printed circuit boards or busbars, accepts a wide range of wire gauges, and provides easy cable assembly management is a challenge. SW1 offers locking pins that can attach to either printed circuit boards or busbars. The SW1 receptacle assemblies accept wire gauges ranging form 2 AWG to 4/0 AWG. SW1’s unique positive locking design allows cable assembly to rotate freely about the locking pin axis after mating, simplifying cable assembly dressing.

Features & Benefits

- Home Energy Storage

- Industrial Automation

Extreme Power Products

To operate at peak efficiency, today’s data centers require interconnects that can accommodate significant amounts of power. Molex EXTreme Power products are specifically designed to support high-current applications with optimal power densities and exceptional thermal management capabilities. They’re also available in an extensive range of configurations, so customers can continue evolving seamlessly.

EXTreme Ten60Power

EXTreme Guardian

EXTreme PowerEdge

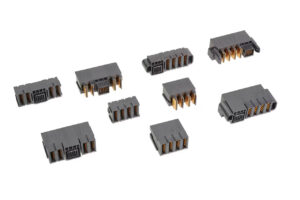

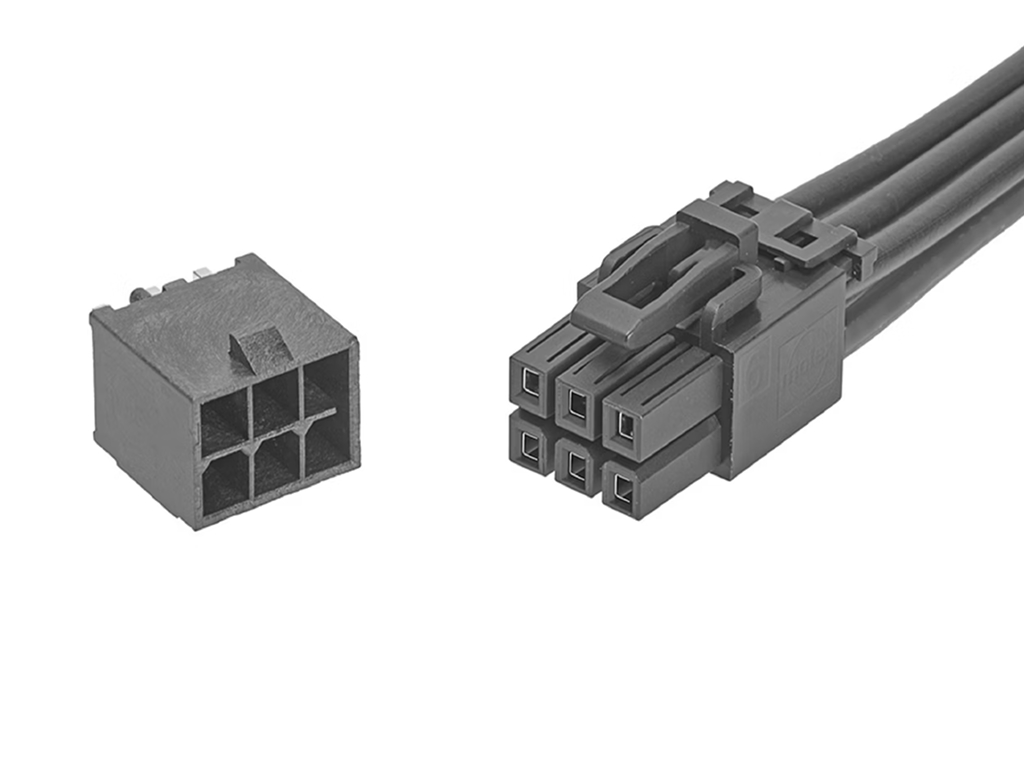

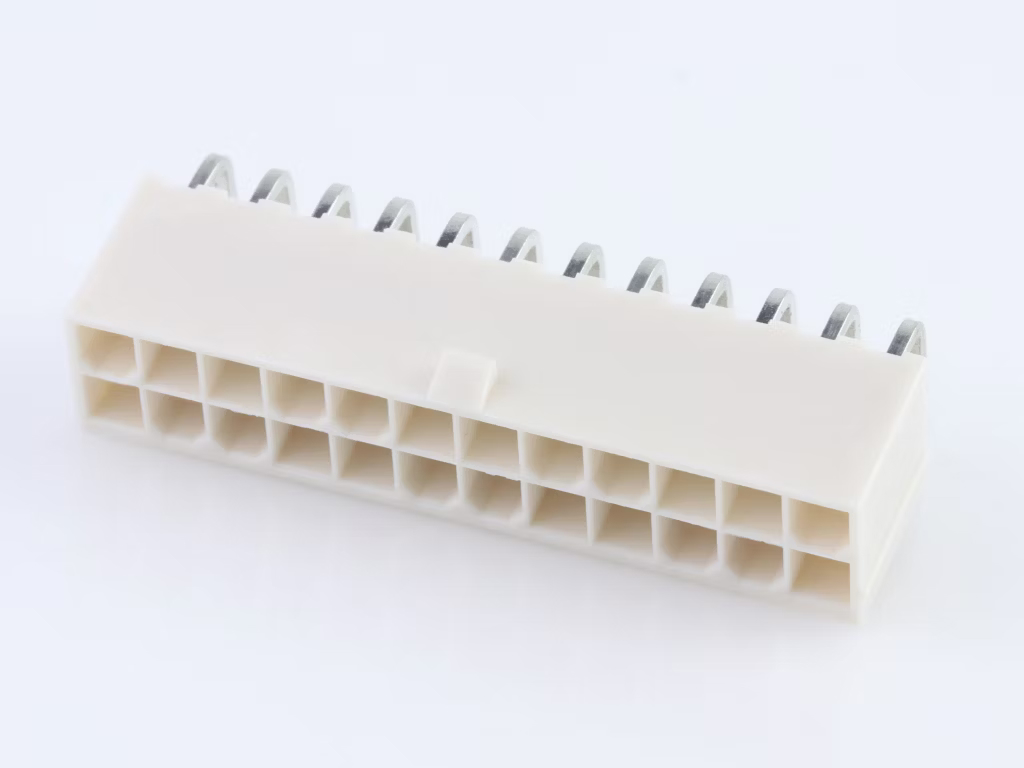

Mini-Fit Connectors

The Mini-Fit Connector family delivers an operating temperature up to +125° C, offers a double crimp tool and is available in Board-to-Board, Wire-to-Board and Wire-to-Wire configurations.

Features & Benefits

Mini-Fit Connectors

- Self-aligning interface Enables operator to mate connectors in hard-to-reach areas

- Polarized mating geometry Ensures header and receptacle cannot be mismated

- Positive locking housings Easy-to-operate thumb latch assures connectors are fully mated Prevents accidental unmating

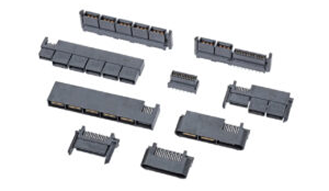

Mini-Fit Max

- End-to-end stackable

Delivers more power per linear inch and square millimeter than other mid-range power connectors - 4 independent points of contact

Offer redundant, secondary current paths for long-term performance and reliability - Tangless terminal

Provides safety for the terminals during packing and assembly insertion

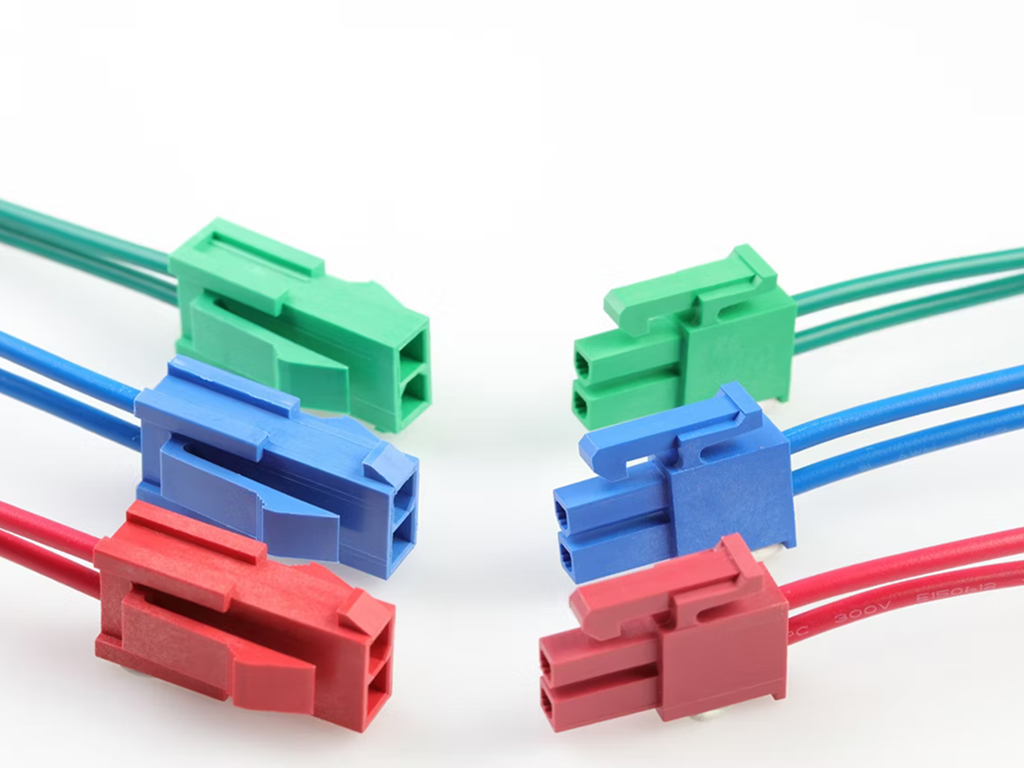

Mini-Fit Versa Color

- Visual color pairing (colors can be intermated)

Ensures proper mating during termination - Panel mount and vertical header options

Maintains current rating through application surfaces or panels - 5 color options

Offers quick identification and ease of assembly

Mini-Fit Sigma

- Panel mount ears

Recommended panel cut-outs for 0.89mm to 3.00mm thick panels with panel cut-out tolerances of +0.10mm

Provides safety and stability of housing to the panel - Seal cap supports

Provides excellent support for the rubber cap that mounts around the back of the housing - Keying and polarization

Allows for accurate mating to standard Mini-Fit 4.2 Power Connectors - Provides a lower mating force contact to improve impact to the operator

The Mini-Fit Sigma Low Mating Force Terminals improve overall assembly ergonomics for production line operators, reducing injury from high-volume assembly or mating of connectors, and providing more overall assembly efficiency

Mini-Fit HCS

- Crimp terminals are produced from a proprietary, high-current alloy Rated up to 13.0A per circuit

- Receptacles and plugs accept standard Mini-Fit and Mini-Fit Plus crimp terminals Reduces the number of parts to be purchased and inventoried

- Terminals feature a patented, elongated dimple design Provide long wipe lengths and increased contact area for improved long-term reliability

BROCHURES AND GUIDES

- Busbar Solutions Brochure

- SW1 High-Current Wire-to-Board and Busbar Interconnects

- SW1 High-Voltage, High-Current Connectors

- COEUR-Enabled High-Voltage, High-Current Connectors

- Power Consumption of Data Centers Driving Change

- EXTreme Power Products

- Mini-Fit Max Connector Brochure

- Mini-Fit Versa Color Connectors