WAGO

For more than 60 years, WAGO has developed and produced innovative products for packaging, transportation, process, industrial and building automation markets amongst others. Aside from its innovations in spring pressure connection technology, WAGO has introduced numerous innovations that have revolutionized industry. Further ground-breaking inventions include: the WAGO-I/O-SYSTEM®, TOPJOB S® and WALL-NUTS®.

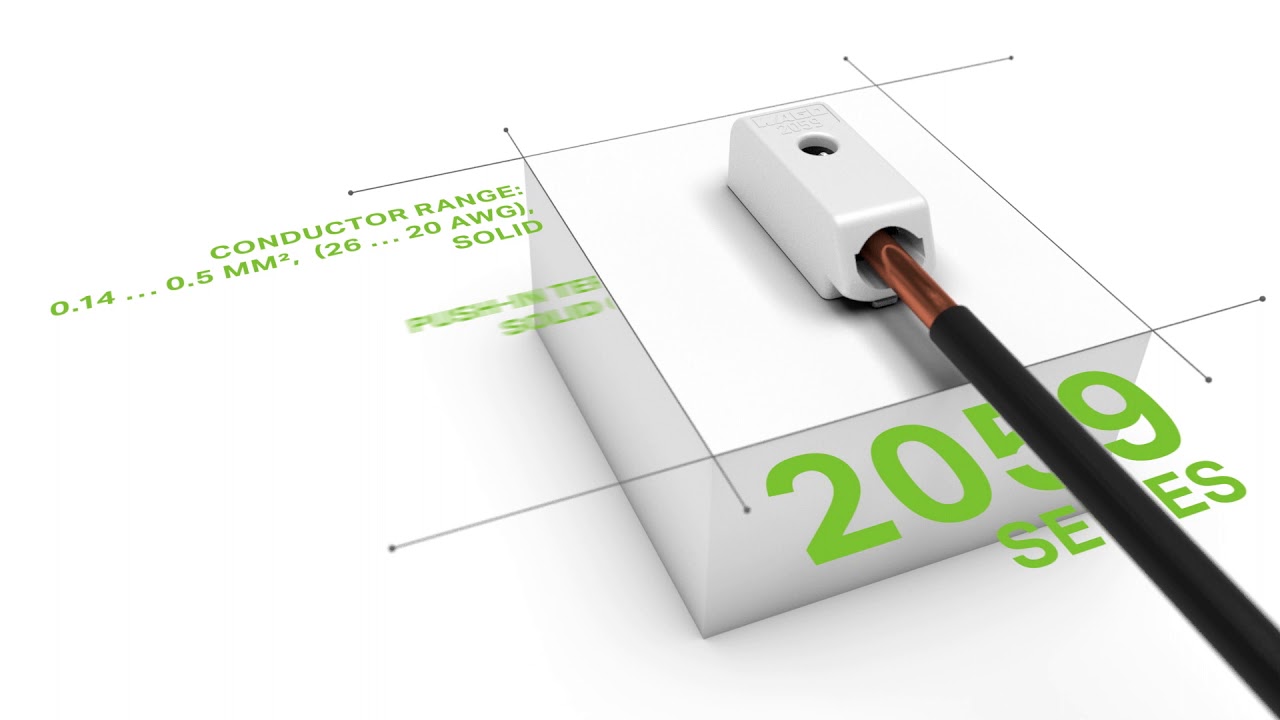

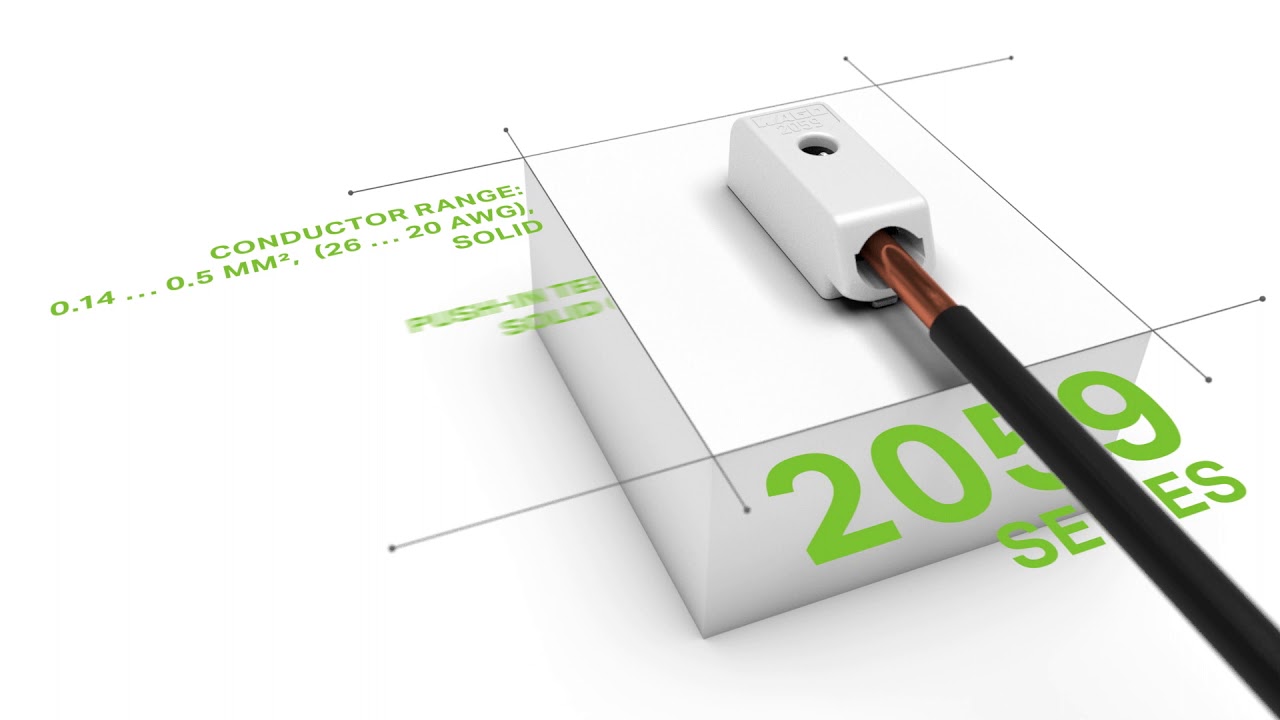

Super-compact, tool-free PCB terminal block that allows for quick and easy wiring for cross-sections from 26 to 14 AWG.

The trend toward ever more compact components also presents new challenges for power electronics. The increased power density brought about by combining the signal and output layer on the PCB also impacts connection systems.

The trend toward ever more compact components also presents new challenges for power electronics. The increased power density brought about by combining the signal and output layer on the PCB also impacts connection systems.

Flexible, Fast and Safe!

Flexible, Fast and Safe!

WAGO’s 221 series compact splicing connectors are designed to easily terminate conductors in 2-, 3-and 5-wire configurations. Pull the lever up, insert a conductor and push the lever back down – done!

WAGO Video

WHITE PAPER: 5 Reasons the 2065 Connector is a Reliable Alternative to Manual Soldering

Due to today’s increasingly automated age, there have been innovations in wave and reflow techniques that are technically sound for certain types of components, but the manual process of soldering yet remains when it comes to connecting flying leads, i.e. wires, to printed circuit boards. When done properly, it is a tried and true connection method that has endured. In this paper, we will explore the challenges encountered when hand soldering, and the WAGO alternative – the 2065 Series Surface Mount PCB terminal block including:

Due to today’s increasingly automated age, there have been innovations in wave and reflow techniques that are technically sound for certain types of components, but the manual process of soldering yet remains when it comes to connecting flying leads, i.e. wires, to printed circuit boards. When done properly, it is a tried and true connection method that has endured. In this paper, we will explore the challenges encountered when hand soldering, and the WAGO alternative – the 2065 Series Surface Mount PCB terminal block including:

- Hand soldering is not repeatable

- Soldering is hot and it can get that way quickly

- Cold solder joints are unseen dangers

- Too much solder is suboptimal

- Too little solder is suboptimal

Browse Our Product Video Spotlights

WAGO Video Series Playlist:

1:21

0:56